Customer Case

Customer Case

Customer Case

Customer Case

Customer Case

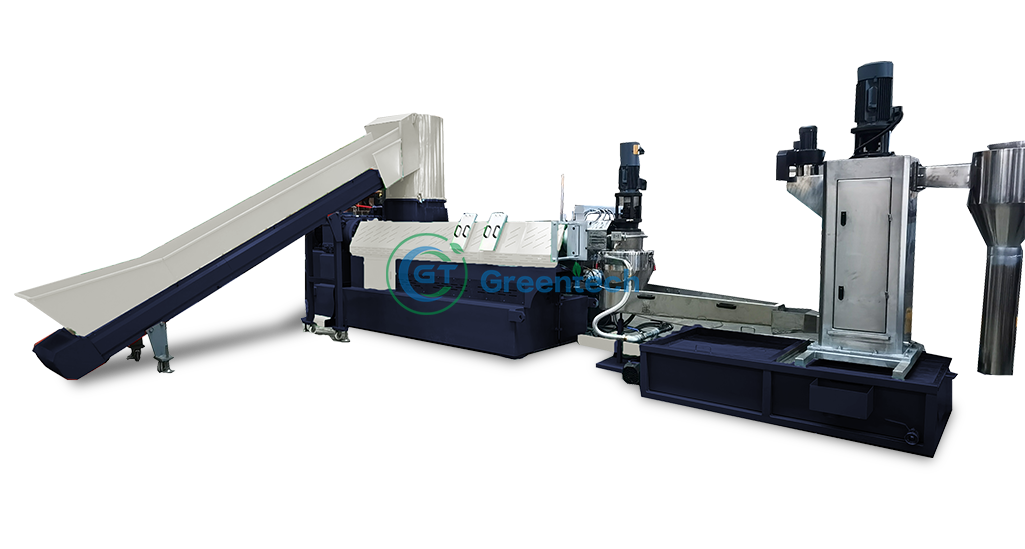

farm film shredder

there are much sand, soil, dirty on farm film, the wear for the cutter blade is very quick

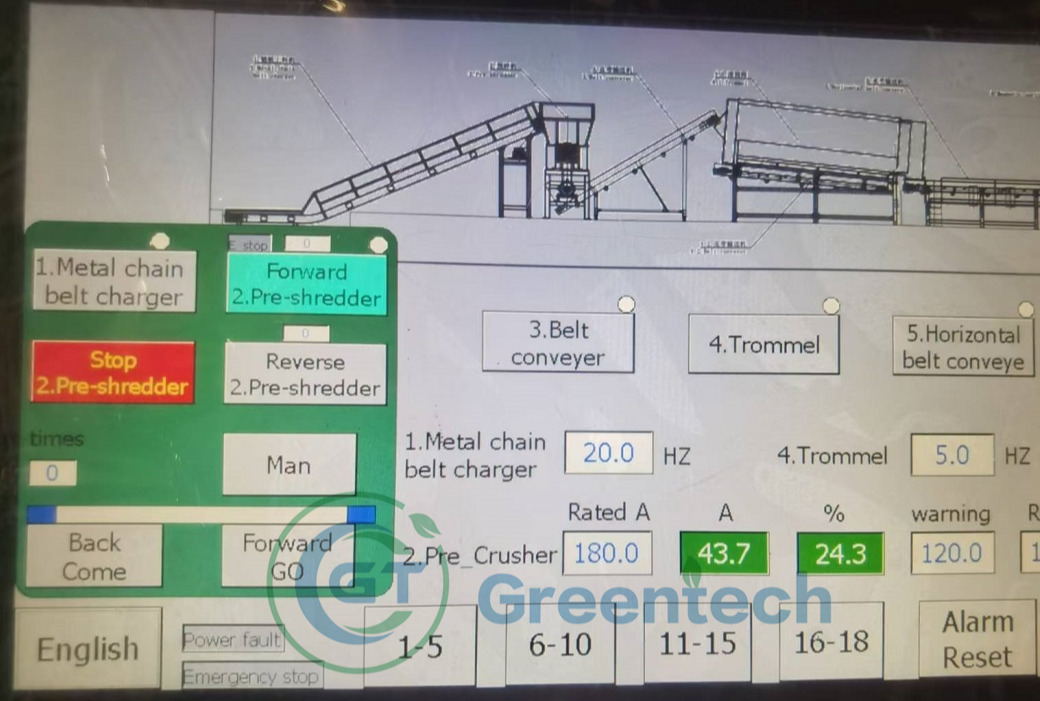

Agriculture film bag washing

The used consume film, bag contain much impurity, the first step to recycle is not by water, but by pre-washer to dry deal first

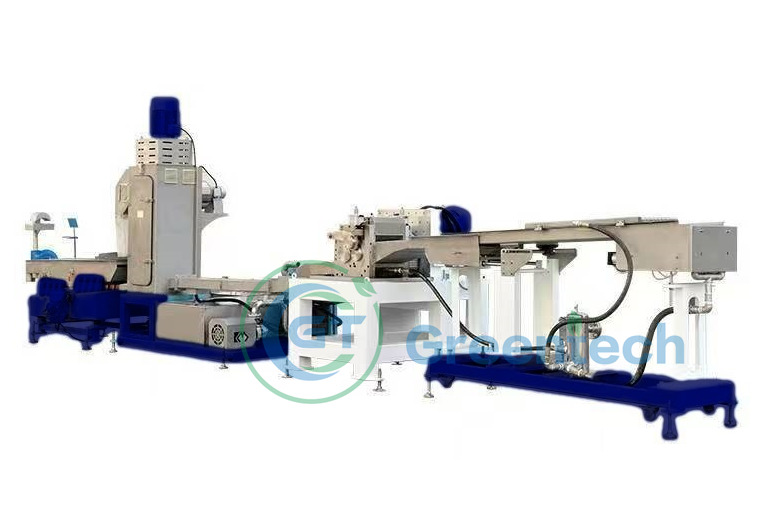

Laser screen changer on pelletizing machine

Laser filter can remove contaminants or oversized particles, ensuring high-quality pellets are produced

The Imperative of Plastic Recycling

Plastic make life more convinece and easier, the improper way to deal the plastic make our environment much problems

Recycle and Wash Used PP Woven Bags

PP woven bags, commonly used for packaging, transportation, and storage, are versatile and durable, making them perfect candidates for recycling and reuse

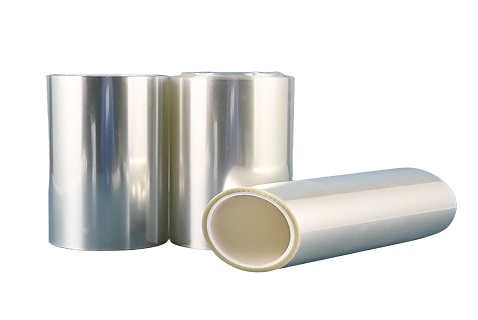

Polyethylene (PE) recycle

PE is most widely using in our daily life, many products are made by PE, it is economic and easy to produce

injection Mould flakes granulator

Many types mould products like fruit basket,pallet,chair, food package, juice milk bottle can be recycled and reuse again

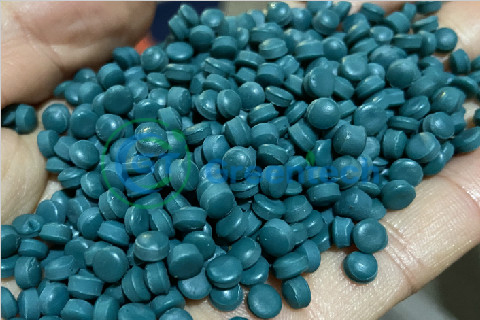

PE CaCo3 FILM PELLETIZING MACHINE

the cut off edge PE film with CaCo3, by special design and wearable bimetallic screw

cutter on pelletizer

There are many types cutting methods in pelletizing :normal noodle cutter or under water noodle cutter, under wa

BOPET recycling

BOPET melt temperature around 250°C to 290°C, recycled BOPET has much application in many fields

Plastic category

Plastics are often classified asPolyethylene (PE)Polypropylene (PP)Polyvinyl chloride (PVC)Polystyrene (PS)Polyethylene