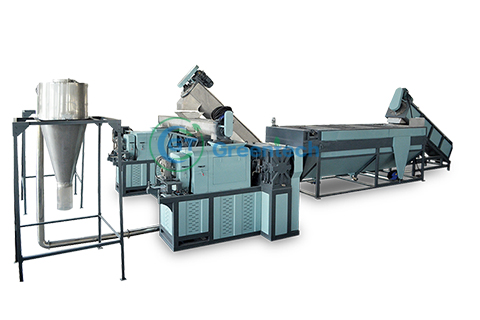

Plastic Hard Rigid Washing

PP Polypropylene

ABS Acrylonitrile Butadiene Styrene

PS Polystyrene

PC Polycarbonate

PET Polyethylene terephthalate

Mould

Injection

Hollow

Milk, Shampoo, water bottle

Standard washing line

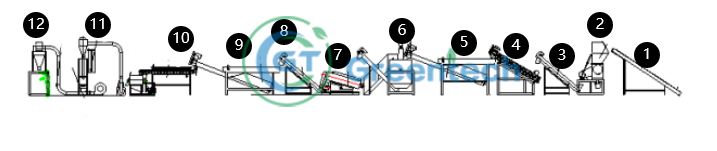

1.Belt conveyor

Transport the material to the crusher. Belt can be PVC or Rubber material

2.Crusher

Crush plastic bottle,tank, barrel, if the raw material is large and output higher, suggest by shredder, then connect with shredder

3.Screw loader

The small flakes are washed by friction

4.High speed friction

The small flakes are washed fully by second time friction.

5.Floating tank

Remove the dirty on the flakes surface

6.Hot washer

Hot hot and some chemical can make material cleaner. This step is usually necessary for PET, PP PE bottle, tank can be added too

7.Friction washer

By high speed friction and remove the dirty water

8.Screw loader

Transport the washed flakes

9.Floating tank

Twice rinse the flakes in water to remove the rest dirty. This step can be saved or Thrice to strengthen the clean.

10.Spray washer

Third time wash to ensure the clean, this step can be saved by material condition.

Remove the water on material, final moisture 3-5%, which can go to extruder directly

11.Label remover

Remove label to get purity flakes

12.Silo

For packing or next transition

|

Bale opener |

Option |

|

Belt Conveyor | |

|

Trommel | |

|

Belt Conveyor | |

|

Magnetic separator | |

|

Bottle Label Remover | |

|

Belt Conveyor | |

|

Pre-washer | |

|

Belt Conveyor | |

|

Manual Sorting Belt | |

|

Belt Conveyor |

Basic configuration |

|

Crusher | |

|

Horizontal Screw Loader | |

|

Screw Loader | |

|

Floating Washer | |

|

Medium Speed Friction Washer | |

|

Hot Washer | |

|

High Speed Friction Washer | |

|

Screw Loader | |

|

Round floating tank | |

|

Floating Washer | |

|

Centrifugal Dryer | |

|

Label Flake Separator | |

|

Vibrating Packing System | |

|

Electric Cabinet |