Plastic Film Washing

PP Polypropylene Film

BOPP Biaxially Oriented Polypropylene Film

PA Polyamide film

PP woven bag

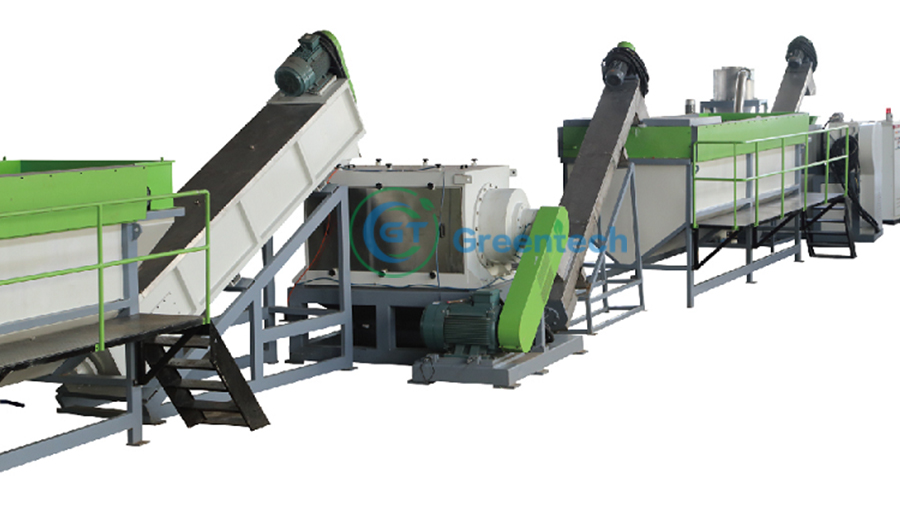

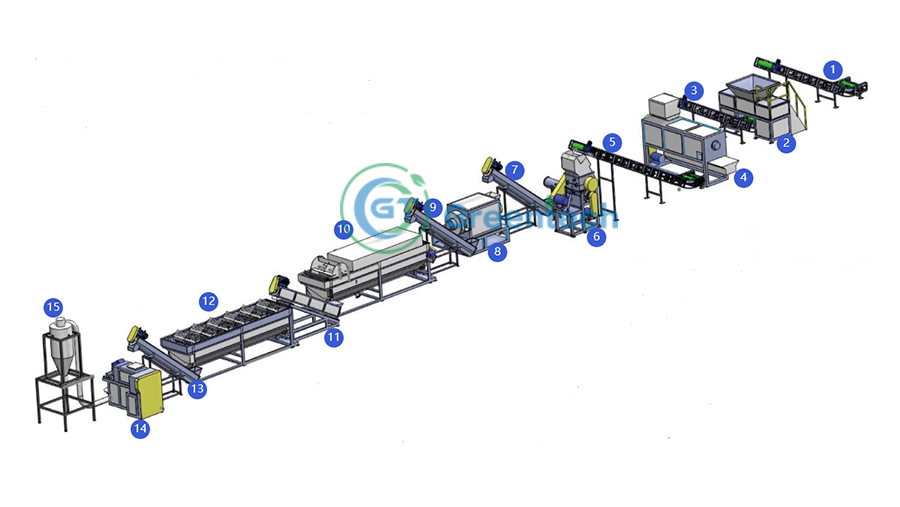

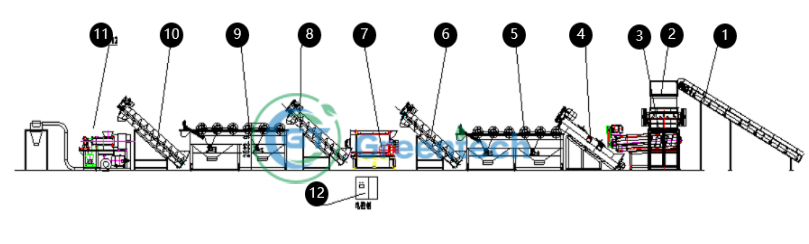

1.Belt conveyor

Transport the material to the crusher. Belt can be PVC or Rubber material

2.Crusher

Crush plastic film, woven bag

3.Friction washer

The small flakes are washed by friction

4.High speed friction

The small flakes are washed fully by second time friction.

5.Floating tank

Remove the dirty on the flakes surface

6.Screw loader

Transport the material

7.Dewater

Key function is to remove the dirty water

8.Screw loader

Transport the washed flakes

9.Floating tank

Twice rinse the flakes in water to remove the rest dirty. This step can be saved or Thrice to strengthen the clean.

10.Screw loader

Transport the clean material

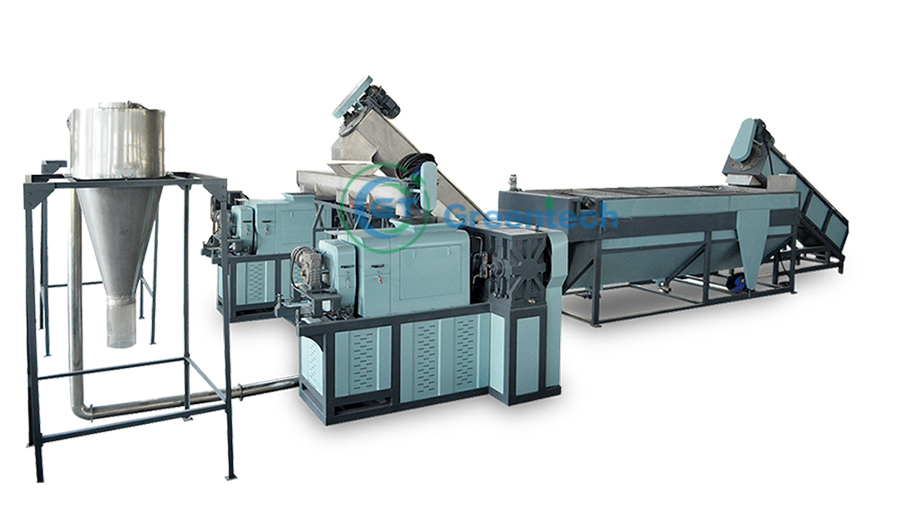

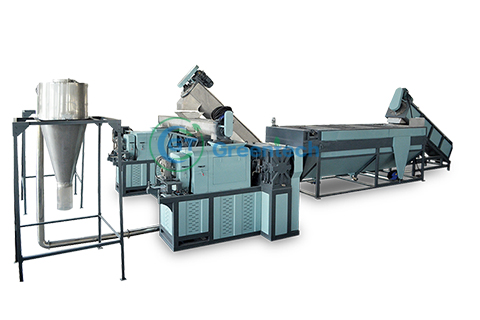

11.Squeezer dewater

Remove the water on material, final moisture 3-5%, which can go to extruder directly

12.Electrical cabinet

Can be PLC or normal control, electrical brand can be Chinese or appointed

|

Hydraulic cutter/ Pre-shredder |

Pre- washing |

|

Belt conveyor | |

|

Trommel | |

|

Belt conveyor | |

|

Single shaft shredder | |

|

Belt conveyor | |

|

Dry sand remover | |

|

Horizontal Belt conveyor | |

|

Belt conveyor |

Mainly washing |

|

Crusher | |

|

High speed screw washer | |

|

High speed screw washer | |

|

Dewater | |

|

Screw charger | |

|

PE floating tank A | |

|

Low speed washer | |

|

PE floating tank B | |

|

Screw charger | |

|

Horizontal screw charger | |

|

Squeezer | |

|

Electrical cabinet |