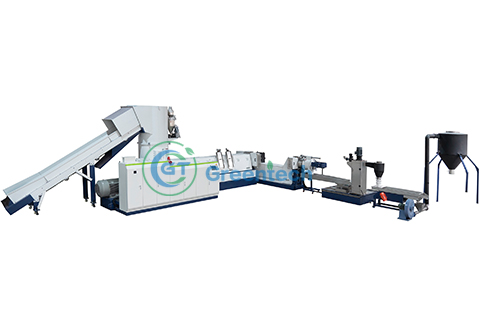

Plastic Film Pelletizing Machine one stage

PE Polyethylene Film PP Polypropylene Film BOPP Biaxially Oriented Polypropylene Film PA Polyamide film PP woven bag PP non woven Clean Wrong cut off Edge cut off Clean Little dirty MFI >15 Noodle cutter MFI<15 Water ring die face cutter

Plastic Film Pelletizing Machine Two stages

PE Polyethylene Film PP Polypropylene Film BOPP Biaxially Oriented Polypropylene Film PA Polyamide film PP woven bag PP non woven Laminated Heavy printed ink Washed Little dirty

Plastic Rigid Pelletizing two stages

PE Polyethylene PP Polypropylene ABS Acrylonitrile Butadiene Styrene PS Polystyrene PC Polycarbonate Mould products Injection products Washed rigid flakes MFI≥15 by normal noodle cutter or under water cutter MFI<15 by die face cutter Screen changer Filter Four plates type filter: Two plates work together to enlarge filter area Advantage: economic and effective

Plastic Rigid Pelletizing Machine one stage

PE Polyethylene PP Polypropylene ABS Acrylonitrile Butadiene Styrene PS Polystyrene PC Polycarbonate Mould products: pallat, barrel Injection products: bottle , tank Clean material Little dirty material MFI≥15 by normal noodle cutter or under water cutter MFI<15 by die face cutter Normal size feeder for rigid size: 5-10mm Enlarged feeder for squeezed agglomerated material

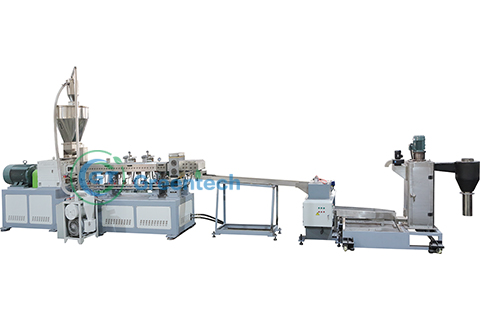

Two Screw Extruder Pelletizing Machine

PET Polyethylene terephthalate Bottle tank fiber CaCo3 Color Master batch Glass fiber compund Mix Filling Normal noodle cutter: Economic and easy operation Under water cutter: Automatic and effective