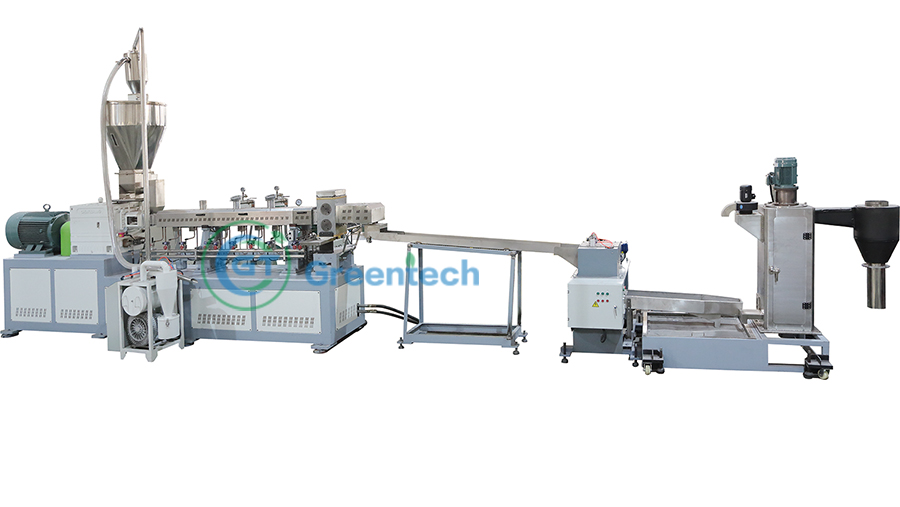

Two Screw Extruder Pelletizing Machine

Bottle tank fiber

CaCo3

Color

Master batch

Glass fiber

compund

Mix

Filling

Normal noodle cutter: Economic and easy operation

Under water cutter: Automatic and effective

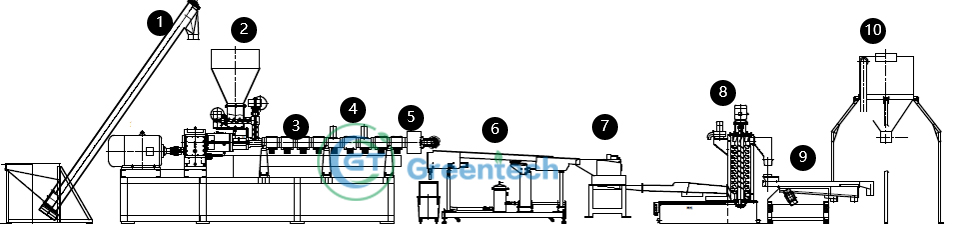

1.Screw loader

Stock the PET flakes or mixed material

2.Feeder

Control speed by inverter, two screw to avoid the bridge, with material level

3.Extruder

Two screw inside the barrel enforce the cut and mix function

4.Vacuum

Normal or strong vacuum depend on material need

5.Screen change

Piston or larger area type filter

6.Cooling tank

Cool and shape the melt plastic material

7.Cutter

Normal or under water cutter

8.Centrifugal dewater

Remove the surface water on pellets

9.Vibrator

Select the even pellets

10.Silo

Store for packing or next using

Specification for

|

Model name |

PET flakes PP PE Compounding Pelletizing machine |

|

Input material/Raw material |

PET bottle rigid, CaCo3,master batch, filling |

|

Output material(mm) |

2-5mm |

|

Final moisture |

1-2% |

|

Capacity (kg/h) |

50-1000 |

|

Feeding |

screw loader |

|

L/D |

40-52 |

|

Heating |

Magnetic/aluminium |

|

Cutter method |

Water ring die face/ Noodle cutter |

|

Degassing |

1-3 |

|

Warranty |

1 year |

|

Delivery time |

60 days |

|

After sell service |

Whole life |