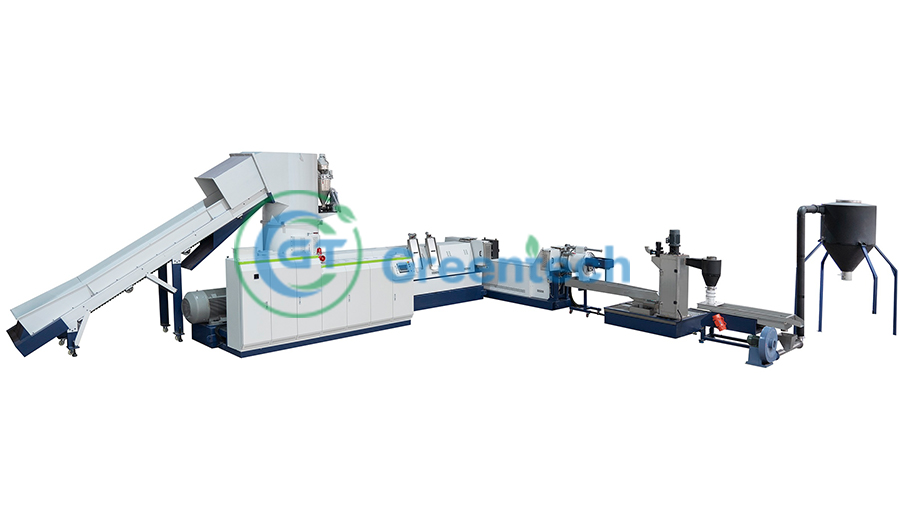

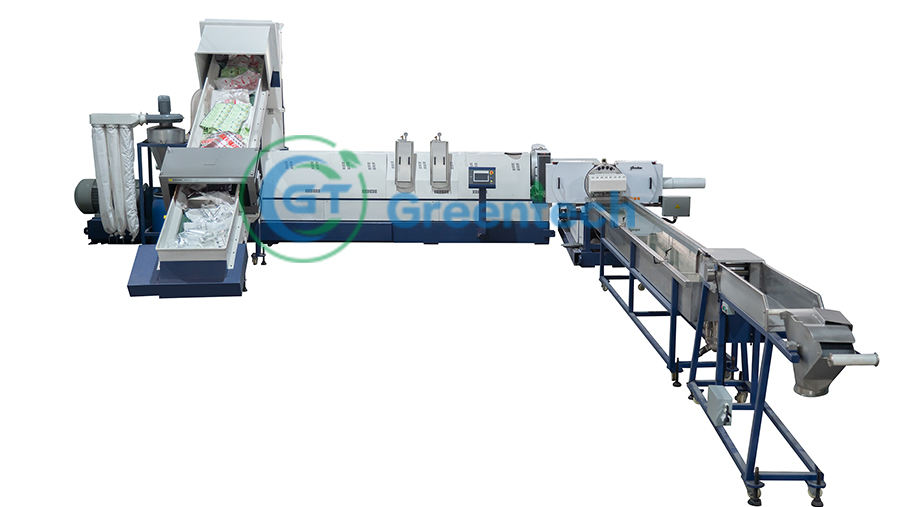

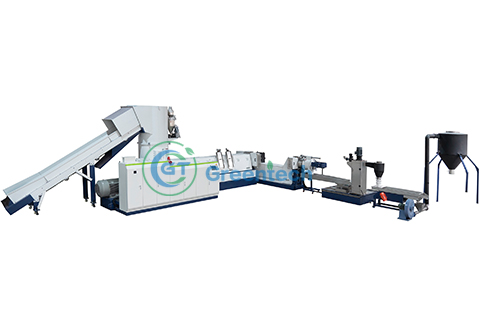

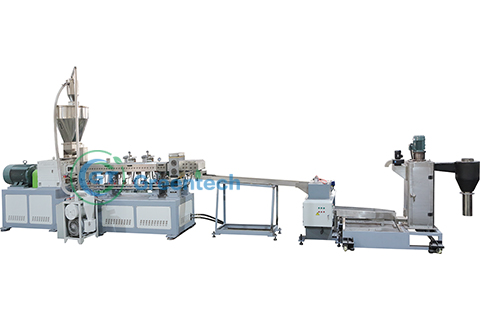

Plastic Film Pelletizing Machine Two stages

PP Polypropylene Film

BOPP Biaxially Oriented Polypropylene Film

PA Polyamide film

PP woven bag

PP non woven

Laminated

Heavy printed ink

Washed

Little dirty

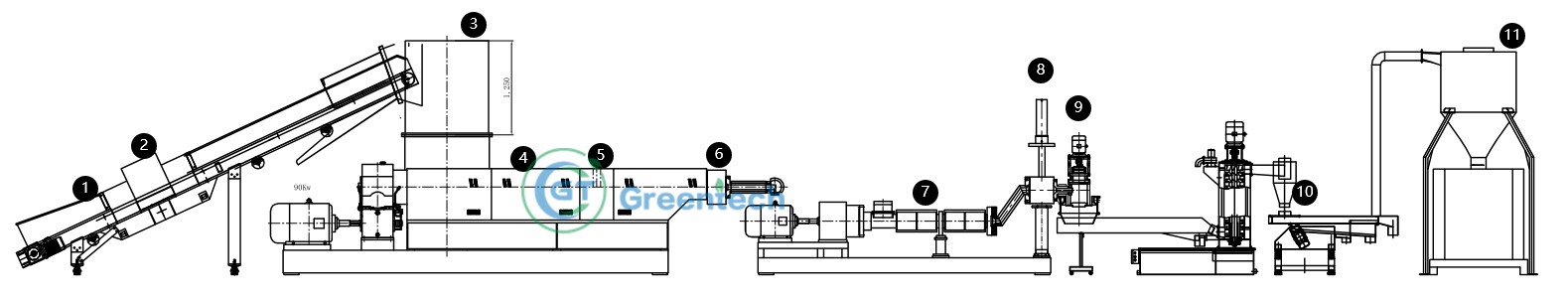

1.Belt conveyor :

Safe and easy operation, the speed of belt can be set, start/stop by APM depending on the amount of material input

2.Metal detector (option):

Once there is metal pass with material, the detector check it and make sound, the belt conveyor will stop automatically

3.Cutting and Compacting

Cutter compactor combine the Cut, dry and compact three functions together, which enables a fast and stable feeding from the compactor directly into the extruder.

4.Extruder

Single screw inside,push the melt material by the force of gearbox and motor

5. Degassing

Able to process films with larger printed area and some water content. Nature degassing, single vacuum degassing or double vacuum degassing can be designed by material’s need.

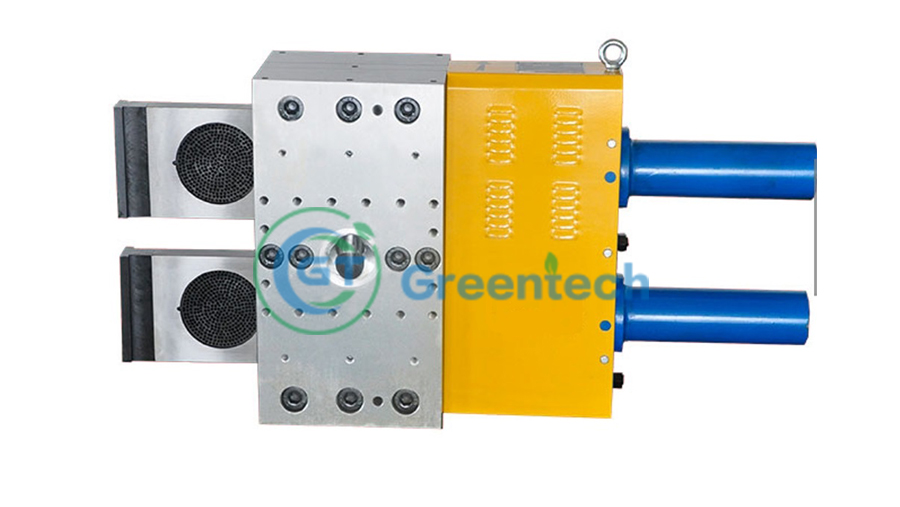

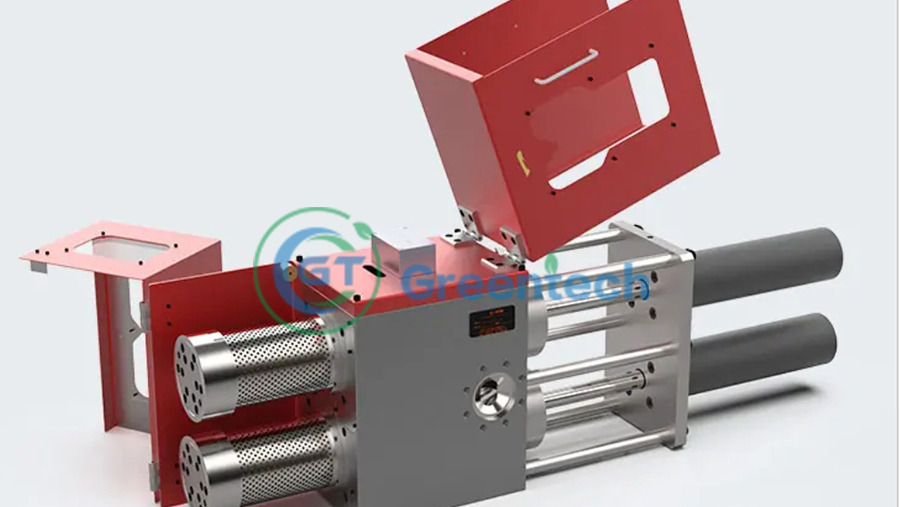

6. Filtration

Screen change with dual channel system: For non-stop operation and prevents material from leaking. Plate type,larger area type, depend on clients’ need.

7.Baby Extruder

Twice extrude for washed or heavy printed film, with better plastify.

With big nature degassing at output to remove humidity or ink.

8. Twice filter

Remove impurity from melt material to enhance the quality and capacity.

9. Pelletization

Produces good shape plastic pellets for reprocessing.

10.Centrifugal dewater/ vibrator dryer

The pellets come from water ring die face cutter with humidity, this step remove the humidity and make pellets dry

11.Storage

The final pellets can be put into bag or send to next processing unit like blow film or make mould

Specification for plastic film pelletizing machine

|

Model name |

plastic film Pelletizing machine |

|

Input material/Raw material |

PP PE film, PP ton bag,BOPP ink,printed film |

|

Output material(mm) |

2-5mm |

|

Final moisture |

1-2% |

|

Capacity (kg/h) |

50-1000 |

|

Feeding |

Belt conveyor |

|

L/D |

25-38 |

|

Heating |

Magnetic/aluminium |

|

Cutter method |

Water ring die face / noodle |

|

Degassing |

1-3 |

|

Warranty |

1 year |

|

Delivery time |

60 days |

|

After sell service |

Whole life |